Centrifugal Pump vs. Positive Displacement Pump

Request a QuoteCentrifugal and positive displacement pumps are powerful tools that can move fluid through complex industrial and municipal systems. But it’s essential to choose the right equipment for your facility’s needs. Here, we’ll discuss the differences between the two pump types, the fluids they can handle, and some of the most popular applications of each pump.

Difference Between Centrifugal Pumps and Positive Displacement Pumps

. Fluid Transfer Mechanisms

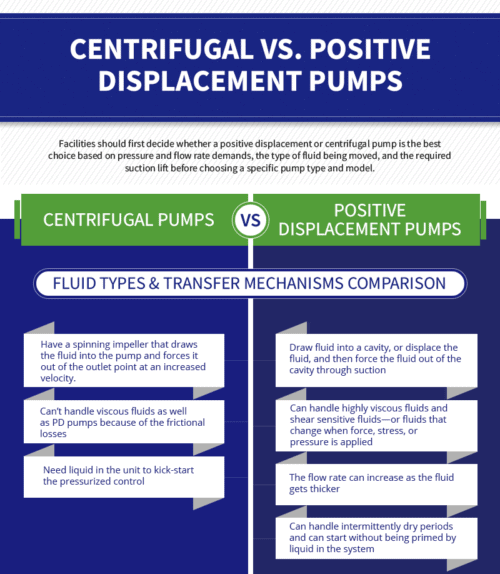

Both centrifugal and positive displacement pumps transfer water from an inlet point to an outlet point at a controlled degree of force and quantity. However, the mechanisms they use are different. Positive displacement pumps draw fluid into a cavity, or displace the fluid, and then force the fluid out of the cavity through suction. Centrifugal, or aerodynamic, pumps have a spinning impeller that draws the fluid into the pump and forces it out of the outlet point at an increased velocity.

. Types of Fluid Transferred

Each type of pump works best with different types of fluid. Positive displacement pumps can handle highly viscous fluids, and their flow rate can increase as the fluid gets thicker. Centrifugal pumps, on the other hand, can’t handle viscous fluids as well because of the frictional losses. Also, positive displacement pumps can handle shear sensitive fluids—or fluids that change when force, stress, or pressure is applied—whereas centrifugal pumps cannot; the impellers present a risk to the fluid. Positive displacement pumps can also handle intermittently dry periods and can start without being primed by liquid in the system. Centrifugal pumps need liquid in the unit to kick-start the pressurized control.

There are several different types of positive displacement and centrifugal pumps, each of which uses slightly different mechanisms and can handle different loads but which still uses the basic concepts of positive displacement and rotational force to cause movement. Facilities should first decide whether a positive displacement or centrifugal pump is the best choice based on pressure and flow rate demands, the type of fluid being moved, and the required suction lift before choosing a specific pump type and model.

Pump Performance Comparison

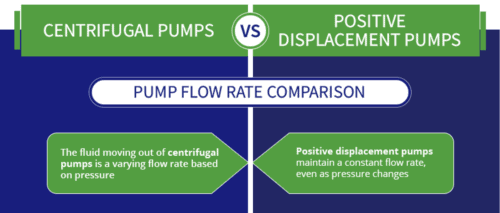

One of the key differences between the performance of positive displacement and centrifugal pumps is the flow rate. Positive displacement pumps maintain a constant flow rate, even as pressure changes, but the fluid moving out of centrifugal pumps is a varying flow rate based on pressure.

Pump Applications

. When to Use a Centrifugal Pump?

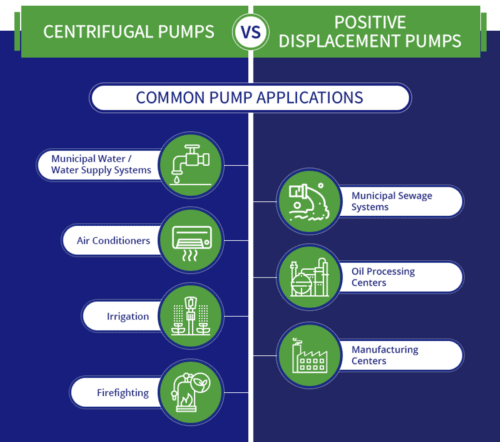

Centrifugal pumps excel at pumping thin liquids with low viscosity levels. These include water, thin oils and fuels, and chemicals. They’re the most commonly used category of pump for high-volume applications that demand high flow rates at low pressures. Some popular applications include:

- Municipal water and water supply systems

- Air conditioners and water circulators

- Irrigation

- Petrochemical and light fuel transfer stations

- Firefighting

- Cooling towers

- Boiler feeds

With a vortex impeller, centrifugal pumps can even handle some fluids with solids. However, they work best when pumping consistent high-volume quantities of water.

. When to Use a Positive Displacement Pump?

Positive displacement pumps, on the other hand, excel at high-pressure and low flow rate applications with viscous fluids. These pumps work well in the following applications:

- Municipal sewage systems

- Oil processing centers

- Manufacturing centers that produce or process thick pastes and other viscous materials

Complex facilities such as food processing plants and other manufacturing facilities benefit from a mix of both types of pumps. Food processing operations will need centrifugal pumps for adding water to batches, for example, but need positive displacement pumps to control the movement of thicker compounds. Oil processing centers may need positive displacement pumps for processing crude oil while they can use centrifugal pumps for handling thinner, lighter by-products.

Quality Pumps From Gainesville Industrial Electric

At Gainesville Industrial Electric, we work hard to provide the right pump for the job. Since 1959, we’ve specialized in providing high-quality motors, pumps, gearboxes, and drives to industrial clients across multiple industries.

Contact Us for Your Pump Needs!

Positive displacement and centrifugal pumps are essential tools for every fluid system. Contact us for expert assistance finding the right pumps for your facility, or request a quote to place your order today.

Related Video:

Related Content: